Quality

Quality management system

Since May 2008 Meccanica Melzani has been operating in compliance with the applicable requirements of the UNI EN ISO 9001 standard. On 08/02/2021 the update of the UNI EN ISO 9001: 2015 standard was updated. Furthermore, we have become an IATF 16949: 2016 certified company. The company quality management system is certified by the DNVGL body.

MECCANICA MELZANI HAS DEFINED A QUALITY MANAGEMENT SYSTEM, AIMED TO ENSURE THAT THE PRODUCTS AND SERVICES OFFERED ARE ADEQUATE TO THE REQUIREMENTS OF THE CUSTOMERS.

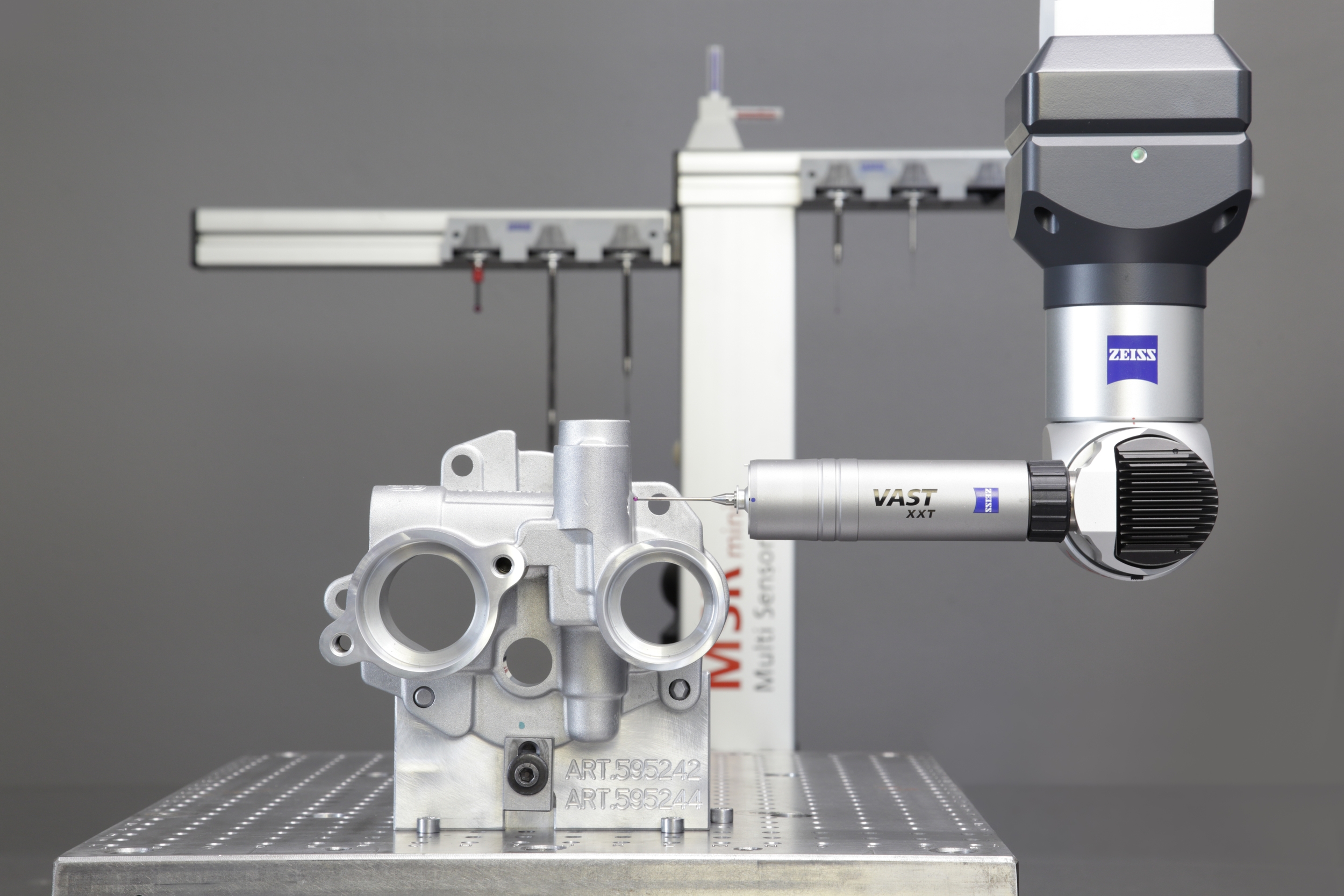

Thanks to the well-tested quality system, all processes are subjected to careful controls, both with the appropriate regularly calibrated and certified measuring instruments (gauges, micrometers, comparators, etc.), and with a continuous scanning 3D measuring machine of the latest generation, placed in an air-conditioned room that guarantees us to monitor all production and present the requested documentation to the customer. As standard, this innovative machine is calibrated annually.

Quality control is monitored from the supply of the material and throughout the production cycle that follows the product up to any external processing.

In our software there are all the controls carried out since the first years of our production activity and the daily control cards are saved, which once completed are digitally archived. The same is also carried out with regard to the Zeiss control reports and the PPAP (Production Part Approval Process) documentation, in order to guarantee the security and availability of documents over time.

Our goals are the full satisfaction of customer expectations and the continuous improvement of our quality performance. For this reason, in addition to maintaining a management system in compliance with ISO 9001:2015 standards, we have implemented the data collection tools following the guidelines of the ISO/TS 16949 standards for customers operating in the automotive sector. In addition, we are in the process of obtaining the ISO IATF 16949: 2016 certification, standard that replaces the old ISO / TS 16949 specification which represents the revised automotive quality management system and is developed by the International Automotive Task Force (IATF).

QUALITY CONTROL & METROLOGY WITH ZEISS

This professional machine monitors the products made and the internal manufacturing processes to ensure that what is then put on the market is a safe and quality product.

Thanks to the innovative efficiency of ZEISS, we have installed PiWeb, a new software that allows you to collect qualitative data in order to perform statistical analyzes . It allows you to organize the flow of information deriving from Industry 4.0 and therefore improve the quality of our products.