FLEET OF MACHINES

We have an efficient and cutting-edge machine park in order to meet the needs of our customers, from the storage of raw materials and semi-finished products, to the processing and delivery of the finished product.

PRODUCTION DEPARTMENT

- no. 5 NH 4000 Mori Seiki horizontal machining centers with continuous table 400×400 mm pallets | strokes from mm 560x560x630 | dimensions of equipment diam. max. mm 630×900 h max capacity 400 Kg

- no. 5 NH 5000 Mori Seiki horizontal machining centers with one grade table 500×500 mm pallets | strokes mm 730x730x850 | dimensions of equipment diam. max. mm 800×1000 h max capacity 500 Kg

- no. 1 VC 510 Doosan vertical machining center with pallet changer strokes mm 762x516x570 | dimensions of equipment diam. max. mm 520×600 h max capacity 350 Kg

- no. 1 VC 430 Doosan vertical machining centers with pallet changer strokes mm 560x430x570 | dimensions of equipment diam. max. mm 460×400 h max capacity 300 Kg

CUTTING DEPARTMENT

• • no. 1 STRONG sawing machine SBA 241 / S Riboni Segartici

QUALITY CONTROL DEPARTMENT

• no. 1 CONTURA G2 Zeiss three-dimensional measuring machine Zeiss

WAREHOUSE AND LOGISTICS DEPARTMENT

• no. 1 Caterpillar NSP16NS forklift truck

• no. 1 Mitsubishi FB20CN forklift truck

• no. 1 Mitsubishi FB20ANT forklift truck

• no. 1 Atleon Nissan truck

• no. 1 Hilux Toyota truck

• no. 1 Ford Transit Connect truck

OUR LATEST NEWS!

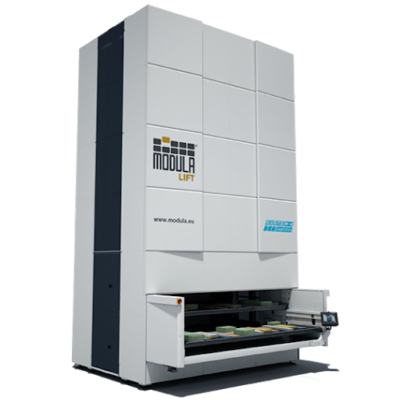

NEW MODULA WAREHOUSE

In order to optimize the management of our warehouse and minimum stocks, we have installed “Modula LIFT”, the new vertical automatic warehouse designed for internal company logistics.

Equipped with internal multi-compartment drawers, it allows you to store goods vertically, saving up to 90% of space on the ground, securing goods and operators, thus becoming an indispensable tool for all supply chain management with enormous advantages in terms of savings, efficiency, safety and cleanliness. Furthermore, it is connected to our new Prodware management system which allows us to prepare and digitally arrange the various work tools, thus being able to monitor the state of supply of materials and make any reorders.

WHASHING SYSTEM

In order to meet the demands of the market, but above all of our customers, we have recently installed a vacuum cleaner, modified alcohol mod. KP 100 HMA of I.F.P.Europe with special washing specifications. In fact, it allows us to offer a more efficient and complete service, being able to carry out only third party washing cycles.

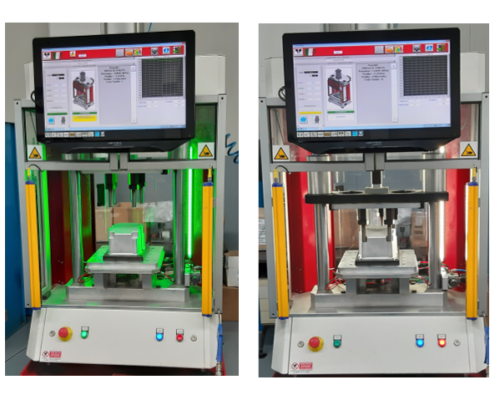

SEAL TEST MACHINE

The TWINS leak testing machine model TB1-112, is a single testing station, dedicated to the control of small and medium production. Its dimensions and the lack of a base on the ground allow it to be inserted directly into production lines or alongside processing or assembly machines for immediate testing of the product.

Its main features are:

– Manual or robot loading

– Pneumatic system integrated into the structure and protected from the environment

– Printing of production parameters and test certificates

– Pneumatic or CNC locking and handling actuators

– Quick change equipment on fixed position or on pallet

– Possibility of guided valve calibration

PRODWARE MANAGEMENT & I-MAN

From 2020 Meccanica Melzani, thanks to interfacing with the Prodware management system and the I-MAN (Interactive Manufacturing) platform, has become Industry 4.0. An innovative company that wanted to exploit its technologies and thus use them in the production process to make it fully automated and interconnected. I-Man is the solution that allows you to better organize production and interact with the employees of the various processing departments. This system consists of wireless touchscreen terminals capable of interfacing directly with the management system to receive and transmit information. All information entered in I-Man is processed by the central system and reaches the production staff in real time.